WPC/PVC/PE/Wood Plastic Powder Profile/Decking/Wall Panel/Foaming Board/Plate/Ceiling Double Screw/Twin Screw Extrusion Making Machine/Extruding Production Line

Basic Info.

| Model NO. | WS |

| Screw | Double-Screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Voltage | Customizable |

| Inverter | ABB |

| Delivery Time | 20 Days |

| Motor | Siemens |

| Electric Parts | Siemens |

| Color | Customizable |

| Transport Package | Wooden Box |

| Specification | SJZ55/110, SJZ65/132, SJZ80/156, SJZ92/188 |

| Trademark | WINSOAR |

| Origin | China |

| HS Code | 847720 |

| Production Capacity | 50sets/Month |

Packaging & Delivery

Package Size 100000.00cm * 2000.00cm * 2000.00cm Package Gross Weight 20000.000kgProduct Description

The plastic ceiling panel production line can produce various kinds of decorative ceiling panel , wall panel and profiles, which are widely used for decorating and protecting the external surface of houses, office buildings, top class villas. It can be laminated with PVC, ASA, PMMA material etc. on the surface. It can be used in hot or cold, dry or wet area, which can bear long period irradiation of ultraviolet radiation and bad weather such as gale and rainstorm, long life and easily to operate. And it also has the advantages of good fireproofing, high capacity, easy installation, low price and long using life.

PVC WPC door board machine production line is mainly used for making WPC door board with different width and thickness. The surface of door board can be treated by printing & coated with glossy oil, heat transfer printing or lamination, which can help the door panel get good decorative effect for house door, kitchen, toilet, balcony and so on.

Features:

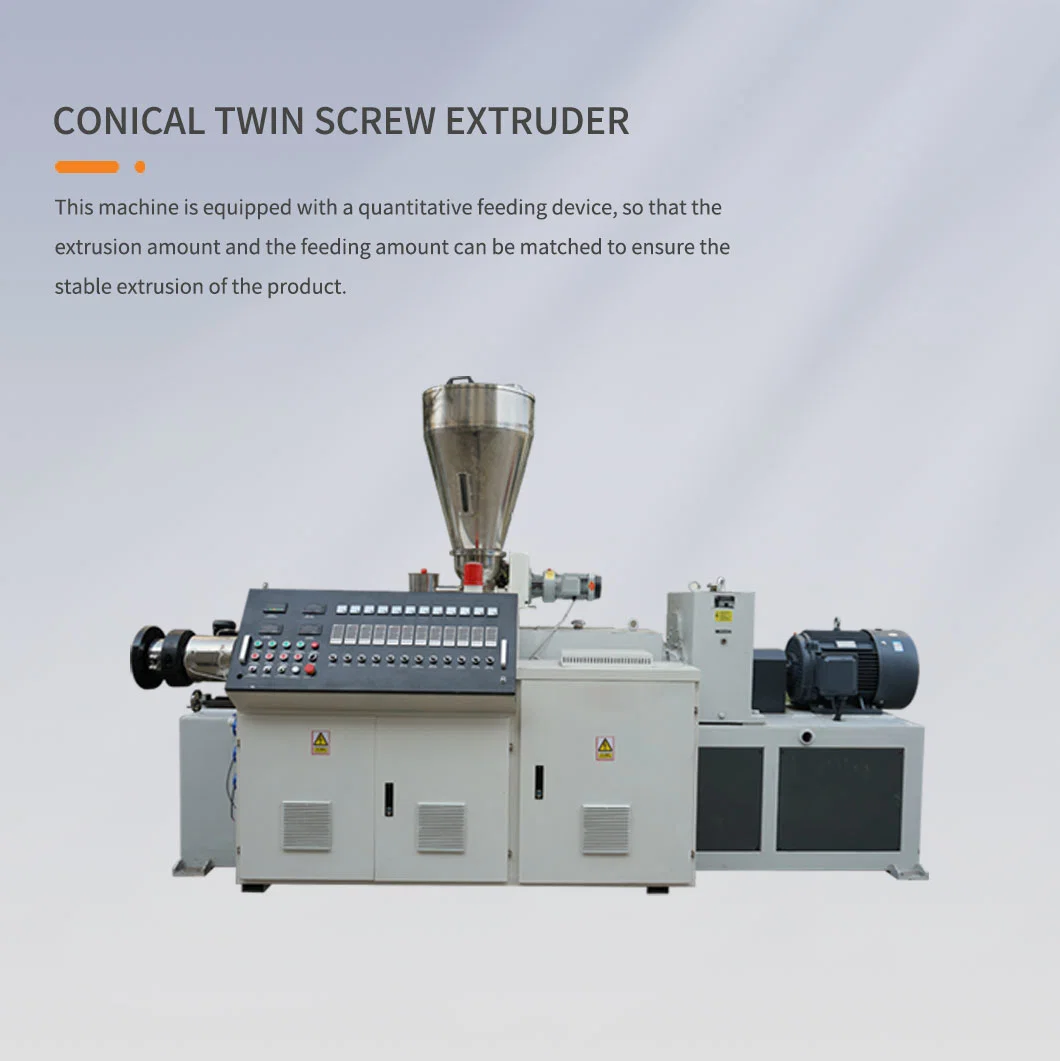

1. Barrier type screw, by which the material can get good plasticizing at low temperature but high extrusion output.2. Barrel with feeding groove, material is 38CrMoAl and nitrogen treated, surface hardness is HRC 65-68, which can has a long use life.

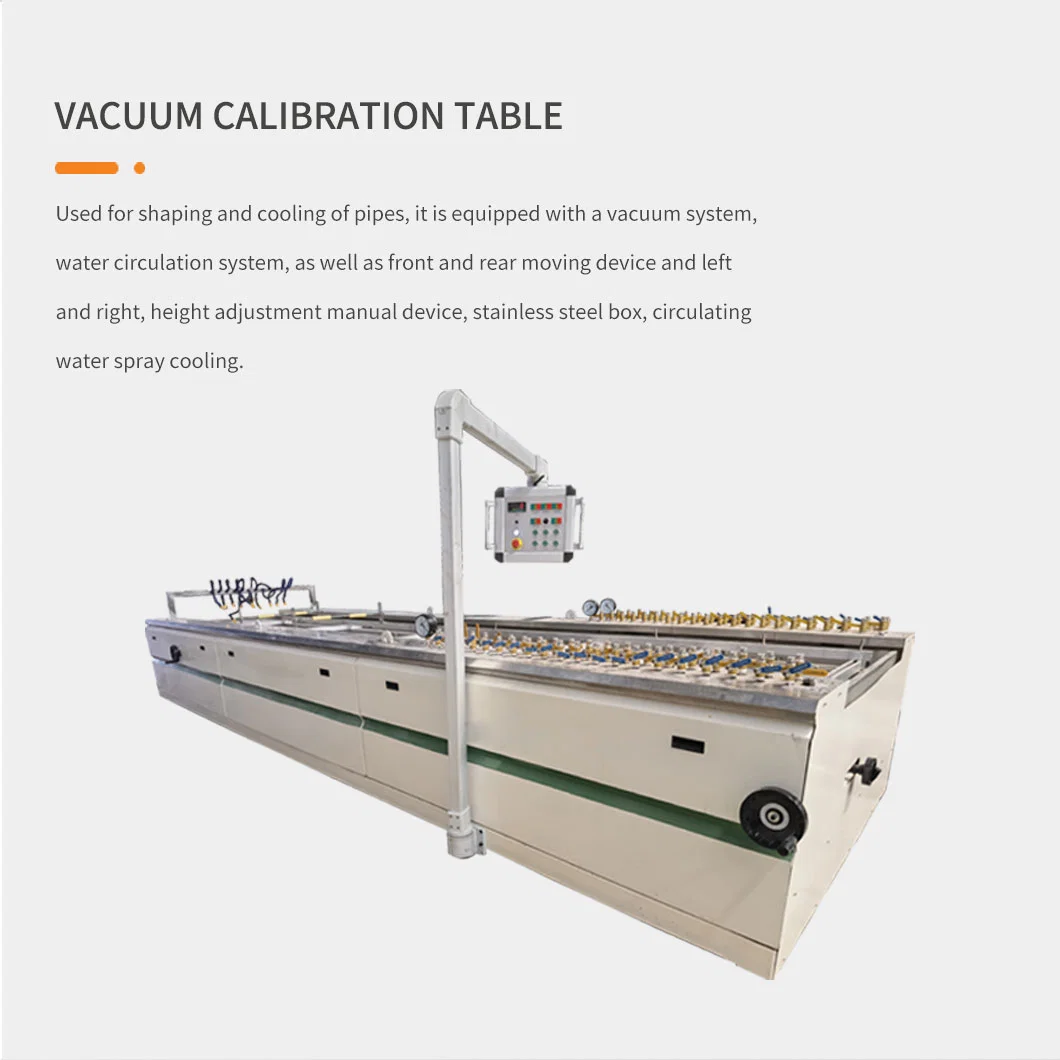

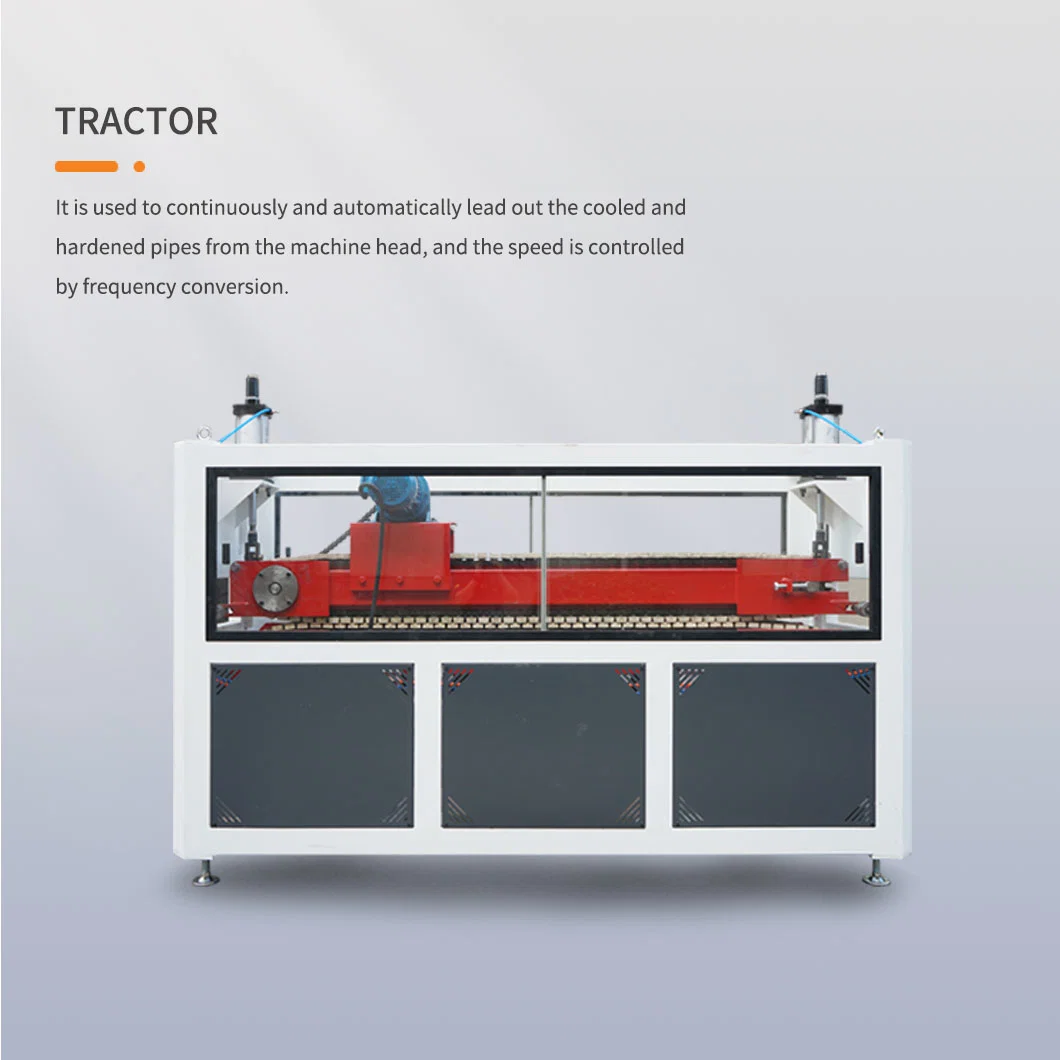

3. Gearbox with nice outline, stable running, low noise and long service time.4. Heating system: adopting cast aluminum heaters with stainless steel plate covers, wind fan cooling system, ensuring good features of cooling and heating, precision temperature controlling.5. Driving system: adopting Siemens motor, using ABB inverter which provide stable torque output and various speed.6. Vacuum calibrating and cooling Table: the table is made by #304 stainless steel, good strength and performance, long life time.7. Traction machines: Rubber block traction belt, traction speed is adjustable by ABB frequency inverter.8. Cutting machine: saw blade cutting, low noise, quick cutting performance, with dust collection device.

Technical Parameter:

| Model | Width | Extruder model | Motor power | Output |

| WS-600 | 400-600mm | 65/132 | 37kw | 220kg/h |

| WS-1200 | 600-1200mm | 80/156 | 55kw | 400kg/h |